Clamp On Ultrasonic Flow Meter

- Accuracy:Better than 1.0 %

- Repeatability:0.2%

- Velocity:+/-32m/s

- Measurement Period:0.5S

- Measurement Principle:Transit-time measurement principle

.jpg)

.jpg)

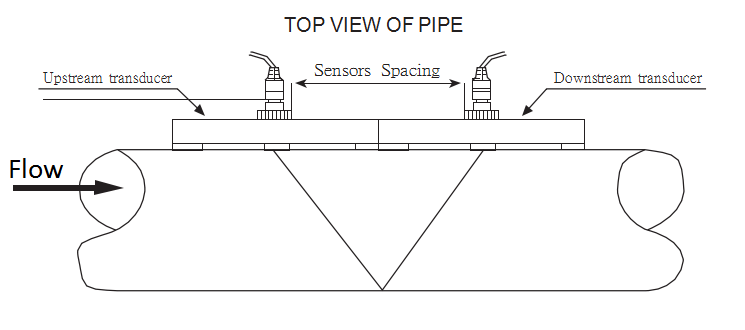

V-method installation is the moswidely used mode for daily measurement with pipe inner diameters ranging from 15 millimeter to 200 millimeter. It is also called reflective mode or method.

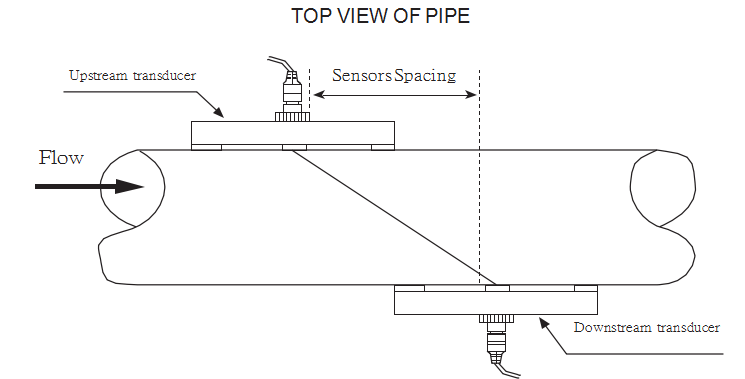

Z-method is commonly used when the pipe diameter is between 300 millimeters and 500 millimeters.

W-method is usually used on plastic pipes with a diameter from 15 millimeters to 100 millimeters

.png)

.jpg)

|

Item |

Performance, Parameters |

|

Accuracy |

Better than 1.0 % |

|

Repeatability |

0.2% |

|

Velocity |

+/-32m/s |

|

Measurement Period |

0.5S |

|

Measurement Principle |

Transit-time measurement principle |

|

Display |

LCD with backlight. 2x20 letters. |

|

Keypad |

4x4-key membrane keypad with tactile feedback |

|

Input |

Five channel 4-20mA current inputs for signals such as temperature, pressure, liquid level, and etc.. Accuracy 0.1%. Two of the five input channels are wired to terminal blocks. The remaining three channels are optional. |

|

Outputs |

Analogue output: 4-20mA or 0-20mA current output. Impedance 01k Ohm |

|

Isolated OCT output: for frequency output (0-9,999Hz), alarm driver, or totalizer pulse output, ON/OFF control, etc. Relay output 1A@125VAC or 2A@30VDC. For ON/OFF control, alarm driver, totalizer output, etc. |

|

|

Internal Alarm (Buzzer): user programmable. External Alarm Driver: alarm signal can be transmitted to Relay or OCT output terminals to drive an external alarm. |

|

|

RS-232 serial port. |

|

|

Others |

Capable of offline compensation for flow totalizer, automatic / manual selectable. Self-diagnosis. Automatically record the following information: The totalizer data of the last 64 days / 64 months / 5 years; The power-on time and corresponding flow rate of the last 64 power on and off events. Allow manual or automatic flow loss compensation The instrument working status of the last 64 days |

|

Power |

AC: 220VDC: 8~36VDC or AC7-30V |

|

Power Consumption |

< 2W |

|

Work time |

Continuous |

|

Environment Temperature |

-30-80 Degrees Celsius |

|

Environment Humidity |

85% RH |