electromagnetic flow meter advantages and disadvantages

- Liner Material:PTFE,PFA,FEP,F46,neoprene,rubber

- Size:DN3-3000

- Medium Temperature:-10℃~160℃

- Measuring Tube material:SS 304

- Accuracy:0.5% or 0.2% of the reading value +0.3 m/s

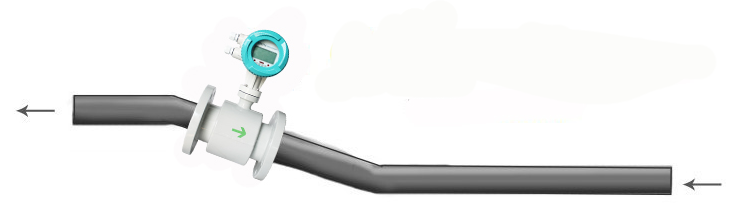

Installation Notice

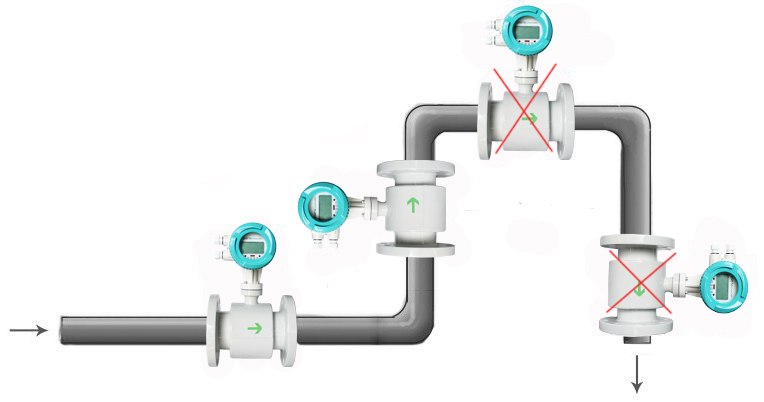

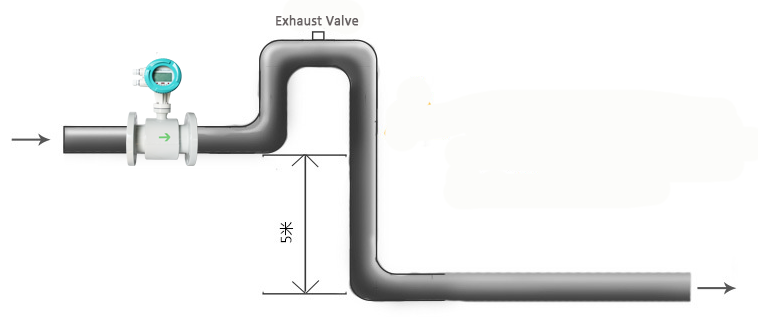

Installed at the lowest point and vertical upward direction Install exhaust valve at the downstreat of flow meter

Don’t install at the highest point and vertical downward diection when drop is more than 5m

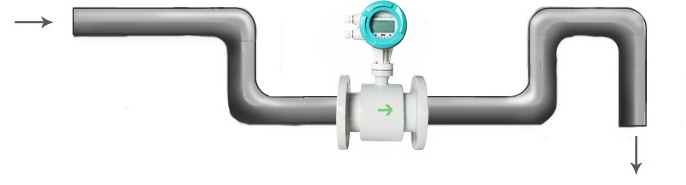

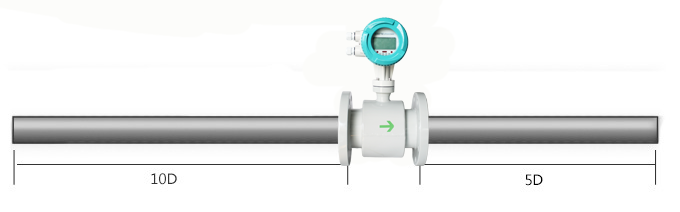

Installed at the lowest point when used in open drain pipe Need 10D of upstreat and 5D of downstreat

exit of pump

.jpg)

|

Size |

DN3~DN200mm |

|

Accuracy |

±0.5% of reading,velocity >0.3 m/s |

|

Conductivity |

Normal liquid >5 μS/cm,DI water >20 μS/cm |

|

Velocity |

0.1 ~ 15 m/s |

|

Structure type |

Integrated, Seperated |

|

Liner Material |

PFA DN3-DN800 (standard) -20℃ ~ +120 ℃ (-68℉~ 248℉) |

|

Electrode Material |

SS 316L (standard),Hastelloy C,Hastelloy B |

|

Body Material |

Stainless Steel 304 (standard),stainless steel 316L |

|

Process Pressure |

0.6 MPa, 1.6 MPa |

|

Frequency Output |

1~5000 Hz |

|

Signal Output |

4~20 mA,pulse |

|

Communication |

RS485/Modbus,Hart over 4~20 mA, Hart,Profitbus |

|

Power Supply |

AC85~250V, DC20V~36V |

|

Ambient Temperature |

-25 ~ +60℃ /-77 ~ 140℉ Sensor -10~ +60℃ /-50~140℉ Convertor |

|

Liquid Temperature |

Integrated: 70℃/ 158℉ max Seperated: 120℃/ 248℉max |

|

Protection Grade |

IP65 Integrated, IP68 Seperated |

|

Connection |

Thread,Tri-clamp |

|

Exciting Current |

125mA, 187mA, 250mA, 500mA |

|

Exciting Frequency |

25Hz, 3.125Hz, 2.5Hz, 2Hz |

|

Straight Pipe |

Inlet Path ≥ 10D, Outlet Path ≥ 5D |

|

Certificates |

CE 6022120716, ISO9001:2008, CQC1500155689521 |

.jpg)

|

Electrode Material |

Applications |

|

Stainless Steel 316L |

Applicable in water,sewage and corrosive mediums.Widely used in industries of petrol,chemistry,carbamide,etc |

|

Hastelloy B (HB) |

Having strong resistance to hydrochloric acid of any consistance which is below bioling piont. |

|

Hastelloy C (HC) |

Be resistant to oxidable acid such as nitric acid,mixed acid,as well as oxidable salt such as Fe+++,Cu++aStnd sea water |

|

Titanium |

Applicable in seawater,and kinds of chloride,hypochlorite salt,oxidable acid (including fuming nitric acid),organic acid,alkali etc. |

|

Tantalum |

Having strong resistance to corrosive mediums that is similar with glass |

|

Platinum-iridium |

Almost be applicable in all chemical mediums except for ammonium salt. |

|

Stainless Steel Covered |

Applicable in mediums of no corrosive and low abrasion. |