electromagnetic flow meter battery operated

- Size:DN3-DN800

- Output Mode:4~20 mA,GPRS,GSM

- Liner Material:PTFE,PFA,FEP,neoprene,hard rubber

- Accuracy:0.5% or 0.2% of reading value +0.3 m/s

- Electrode:SS316L,HC,HB,Tan,Ti,Pt

Introduction

Electromagnetic flow meter is hallmarked by its high performance and reliability based on successful, field-proven technology. It is being widely used in industries such as petroleum, chemical engineering, iron and steel, food, electricpower, paper making, water treatment, petrochemical, medicine etc.

Features

♦ Medium temperature can be -20℃~200℃.

♦ Integrated vertification,diagnostic function and empty pipe detection.

♦ Measure forward and reverse direction flows.

♦ Built-in reference electrodes,no need to connect ground ring.

♦ Dual frequency excitation and stable zero point.

♦ Precision coil winding technology,makes magnetic field more uniform.

♦ High protection grade,IP65.

♦ No moving parts,no pressure loss.

♦ High accuracy: ±0.5% of reading,±0.3% and ±0.2% optional,velocity >0.3 m/s.

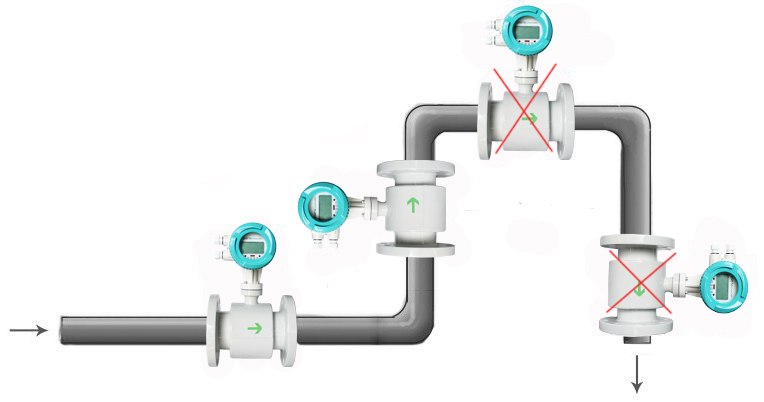

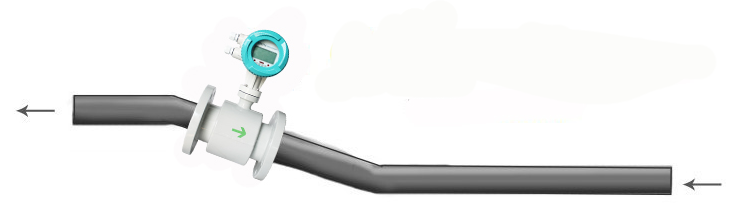

Installation Notice

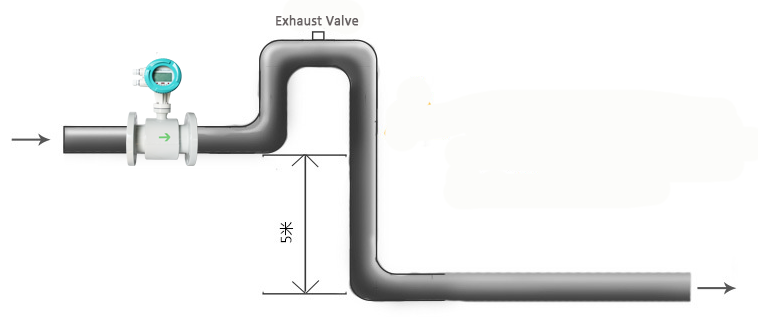

Installed at the lowest point and vertical upward direction Install exhaust valve at the downstreat of flow meter

Don’t install at the highest point and vertical downward diection when drop is more than 5m

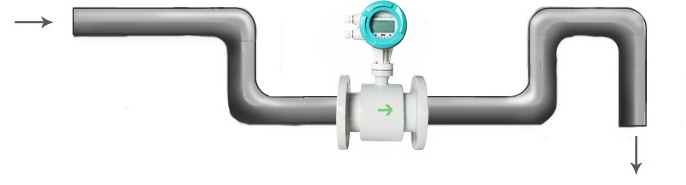

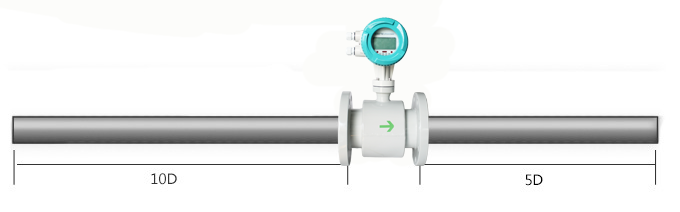

Installed at the lowest point when used in open drain pipe Need 10D of upstreat and 5D of downstreat

exit of pump

.jpg)

|

Size |

DN10-DN800mm (3/8”~32”) |

|

Accuracy |

±0.5% of reading,velocity >0.3 m/s |

|

Conductivity |

Normal liquid >5 μS/cm,DI water >20 μS/cm |

|

Velocity |

0.1-15 m/s |

|

Protection Grade |

IP68 |

|

Power Supply |

Battery-powered |

|

Power Consumption |

<20W |

|

Signal Output |

4~20 mA,pulse |

|

Communication |

RS485/Modbus,GPRS |

|

Language |

English,Chinese (Other languages can be provided on request) |

|

Ambient Temperature |

-25 ~ +60℃ /-77 ~ 140℉ Sensor -10~ +50℃ /-50~122℉ Convertor |

|

Liquid Temperature |

Integrated: 70℃/ 158℉ max Seperated: 200℃/ 392℉max |

|

Relative Humidity |

5%~90% |

|

Measuring Tube |

Stainless Steel 304 |

|

Electrode Type |

Fixed, Scraper |

|

Flange |

Carbon Steel (standard) |

|

Straight Pipe |

Inlet Path ≥ 10D, Outlet Path ≥ 5D |

|

Excitation Frequency |

4.63Hz/s (mode 1), 3.90Hz/s |

|

Electrode |

SS316L (standard), Hastelloy C, Hastelloy B,Titanium Tantalum, |

|

Liner Material |

PTFE DN15-DN1600 -20℃ ~ +120 ℃ (-68℉~ 248℉) |

|

Process Pressure |

4.0 MPa (DN3-DN150) |

|

Flange Standard |

ANSI B16.5 150#, 300#, 600# |

|

Certificates |

CE 6022120716, ISO9001:2008, CQC1500155689521 |

|

Model |

QTLD Bmag S1-P1-L1-E1-B1-F1-X1-C1-D1 |

|||||||||

|

Structure |

Integrated |

S1 |

|

|

|

|

|

|

|

|

|

Seperated |

S2 |

|||||||||

|

Nominal Pressure |

0.6MPa |

P1 |

||||||||

|

1.0MPa |

P2 |

|||||||||

|

1.6MPa |

P3 |

|||||||||

|

4.0MPa |

P4 |

|||||||||

|

Liner |

PTFE DN15-DN1600 -20℃ ~ +120 ℃ |

L1 |

||||||||

|

PFA DN3-DN800 -20℃ ~ +120 ℃ |

L2 |

|||||||||

|

F46 DN25-DN1800 -20℃ ~ +120 ℃ |

L3 |

|||||||||

|

Neoprene DN40-DN3000 -10℃ ~ + 80℃ |

L4 |

|||||||||

|

Polyurethane DN40-DN1600 -10℃ ~ + 60℃ |

L5 |

|||||||||

|

FLS DN40-DN1800 -10℃ ~ + 200℃ |

L6 |

|||||||||

|

Electrode |

Stainless steel 316L |

E1 |

||||||||

|

Hastelloy B |

E2 |

|||||||||

|

Hastelloy C |

E3 |

|||||||||

|

Titanium |

E4 |

|||||||||

|

Platinum-iridium |

E5 |

|||||||||

|

Tantalum |

E6 |

|||||||||

|

Stainless steel covered with tungsten carbide |

E7 |

|||||||||

|

Body Material |

Carbon Steel |

B1 |

||||||||

|

Stainless steel 304 |

B2 |

|||||||||

|

Stainless steel 316L |

B3 |

|||||||||

|

Flange Standard |

ANSI 150#, 300#, 600# |

F1 |

||||||||

|

JIS 10K, 20K, 40K |

F2 |

|||||||||

|

DIN PN10,PN16,PN25,PN40 |

F3 |

|||||||||

|

Commnunication |

RS485-Modbus |

X1 |

||||||||

|

GPRS |

X2 |

|||||||||

|

Connection |

Flange |

C1 |

||||||||

|

Thread |

C2 |

|||||||||

|

Tri-clamp |

C3 |

|||||||||

|

Wafer |

C4 |

|||||||||

|

Electrode Type |

Fixed |

D1 |

||||||||

|

Scraper |

D2 |

|||||||||

Performance of Electrodes

|

Electrode Material |

Applications |

|

Stainless Steel 316L |

Applicable in water,sewage and corrosive mediums.Widely used in industries of petrol,chemistry,carbamide,etc |

|

Hastelloy B (HB) |

Having strong resistance to hydrochloric acid of any consistance which is below bioling piont. |

|

Hastelloy C (HC) |

Be resistant to oxidable acid such as nitric acid,mixed acid,as well as oxidable salt such as Fe+++,Cu++aStnd sea water |

|

Titanium |

Applicable in seawater,and kinds of chloride,hypochlorite salt,oxidable acid (including fuming nitric acid),organic acid,alkali etc. |

|

Tantalum |

Having strong resistance to corrosive mediums that is similar with glass |

|

Platinum-iridium |

Almost be applicable in all chemical mediums except for ammonium salt. |

|

Stainless Steel Covered |

Applicable in mediums of no corrosive and low abrasion. |