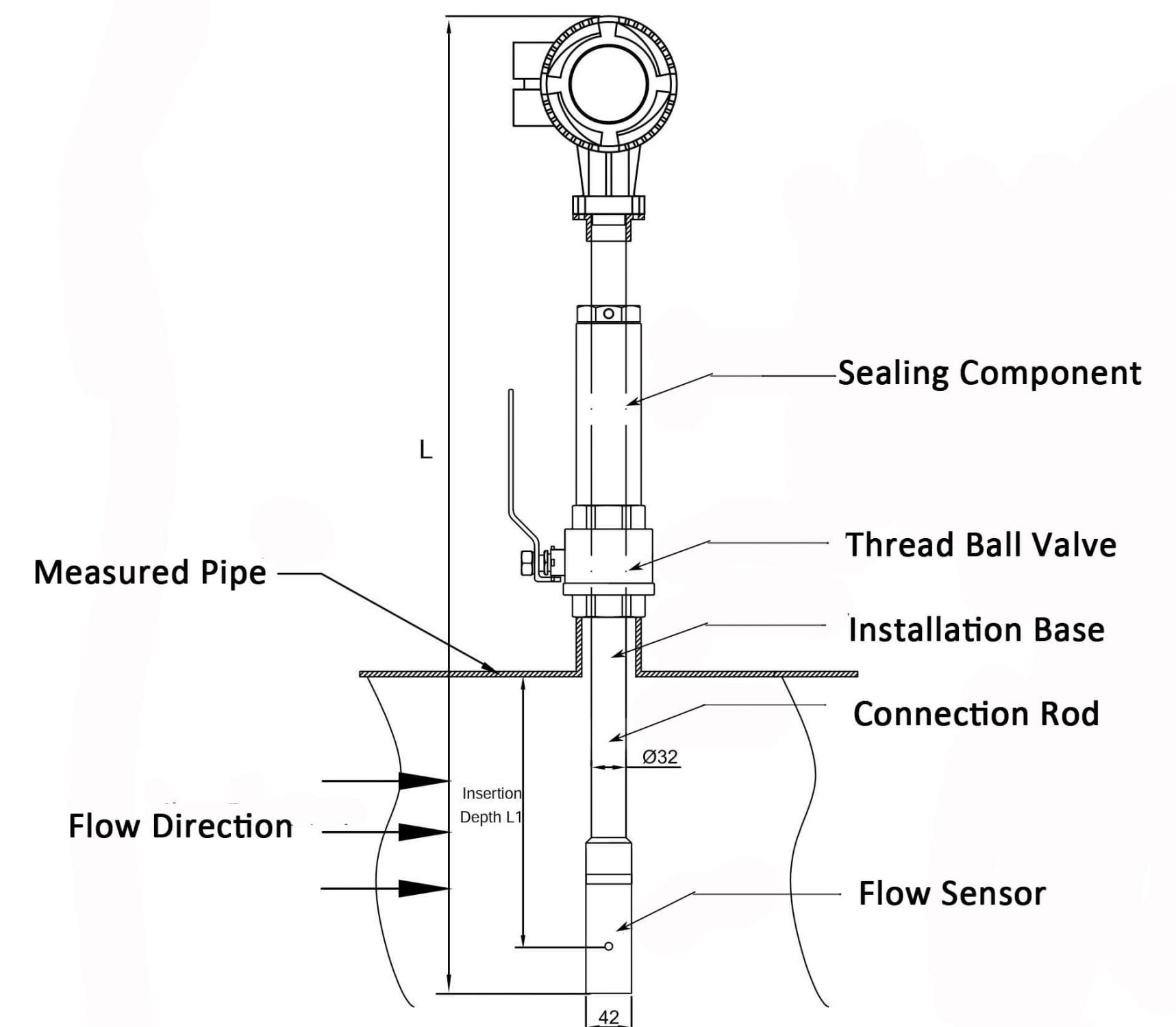

Thread Ball Valve Insertion Electromagnetic Flow Meter

- Size:DN100-DN3000

- Electrode:SS316,HC,HB,Ti,Tan,Pt

- Accuracy:1.5%

- Medium Temperature:-10~160℃

- Velocity:>5 μs/cm

Introduction

Insertion Electromagnetic flow meter is hallmarked by its high performance and reliability based on successful, field-proven technology. It is being widely used in industries such as petroleum, chemical engineering, iron and steel, food, electricpower, paper making, water treatment, petrochemical, medicine etc.

Features

♦ Medium temperature can be -20℃~80℃.

♦ Integrated vertification,diagnostic function and empty pipe detection.

♦ Measure forward and reverse direction flows.

♦ Easy to install and it can be installed without shutting down the process.

♦ Dual frequency excitation and stable zero point.

♦ Precision coil winding technology,makes magnetic field more uniform.

♦ High protection grade,IP65,IP68.

♦ No moving parts,no pressure loss

.jpg)

|

Size |

DN100-DN3000mm (4”~120”) |

|

Accuracy |

±1.5% of reading,velocity >0.3 m/s |

|

Velocity |

Normal liquid >5 μS/cm,DI water >20 μS/cm |

|

Protection Grade |

IP65 (Integrated),IP68 (seperate) |

|

Power Supply |

AC85~250V, DC20V~36V |

|

Power Consumption |

<15W |

|

Communication |

RS485/Modbus,Hart over 4~20 mA, Hart,Profitbus |

|

Language |

English,Chinese (Other languages also can be provided on request) |

|

Display |

LC Display,128X128mm, Three lines, 4 internal push buttons |

|

Ambient Temperature |

-25 ~ +60℃ /-77 ~ 140℉ Sensor -10~ +60℃ /-50~140℉ Convertor |

|

Relative Humidity |

5%~95% |

|

Liquid Temperature |

-20℃-80℃ (-68℉~ 176℉) |

|

Velocity |

0.1 m/s ~ 15 m/s |

|

Max Distance |

50m (sensor and transmitter) |

|

Working Pressure |

≤1.6 MPa |

|

Flange Standard |

DN40,PN16 |

|

Connection |

Simple,Flange ball Valve,Thread Ball Valve |

|

Signal Output |

4~20 mA, Pulse |

|

Grouding Ristance |

<10Ω |

|

Cable Entry |

M20*1.5 |

|

Transmitter Housing Material |

Aluminum |

|

Probe |

ABS |

|

Exciting Current |

125mA, 187mA, 250mA, 500mA |

|

Exciting Frequency |

25Hz, 3.125Hz, 2.5Hz, 2Hz |

|

Electrode Material |

SS316L, Hastelloy C, Hastelloy B,Titanium Tantalum, Platinoiridium, |

|

Body Material |

Stainless Steel 304 |

|

Straight Pipe |

Upsteam Required |

|

Selection Table for Insertion Electromagnetic Flow Meter |

|||||||||

|

Model |

QTLD XXX X X X X X X X |

||||||||

|

Caliber Size |

DN100-DN3000mm |

|

|

|

|

|

|

|

|

|

Nominal pressure |

1.6Mpa |

3 |

|||||||

|

Other |

5 |

||||||||

|

Install Connection |

Flange ball valve |

1 |

|||||||

|

Thread ball valve |

2 |

||||||||

|

Sensor probe material |

ABS |

1 |

|||||||

|

Polypropylene |

2 |

||||||||

|

Electrode |

316L |

1 |

|||||||

|

Hastelloy B |

2 |

||||||||

|

Hastelloy C |

3 |

||||||||

|

Structure type |

Integral type |

1 |

|||||||

|

Remote type |

2 |

||||||||

|

Power Supply |

220VAC 50HZ |

E |

|||||||

|

24VDC |

G |

||||||||

|

Output/Communication |

Flow volume 4~20m ADC/pulse |

A |

|||||||

|

Flow volume 4~20m ADC/RS232C Communication |

B |

||||||||

|

Flow volume 4~20m ADC/RS485 Communication |

C |

||||||||

|

Flow volume HART output/with communication |

D |

||||||||

|

Converter figure |

Square |

A |

|||||||

|

Circular |

B |

||||||||

|

Electrode Material |

Applications |

|

Stainless Steel 316L |

Applicable in water,sewage and corrosive mediums.Widely used in industries of petrol,chemistry,carbamide,etc |

|

Hastelloy B (HB) |

Having strong resistance to hydrochloric acid of any consistance which is below bioling piont. |

|

Hastelloy C (HC) |

Be resistant to oxidable acid such as nitric acid,mixed acid,as well as oxidable salt such as Fe+++,Cu++aStnd sea water |

|

Titanium |

Applicable in seawater,and kinds of chloride,hypochlorite salt,oxidable acid (including fuming nitric acid),organic acid,alkali etc. |

|

Tantalum |

Having strong resistance to corrosive mediums that is similar with glass |

|

Platinum-iridium |

Almost be applicable in all chemical mediums except for ammonium salt. |

|

Stainless Steel Covered |

Applicable in mediums of no corrosive and low abrasion. |