Oval Gear Flow Meter

- Accuracy:±0.2%; ±0.5%

- Nominal Diamete:DN8~DN200 mm

- Nominal Pressure:PN1.6~6.3MPa

- Medium Viscosity:2~3000mPa•s

- Power Supply:12V DC; 24V DC

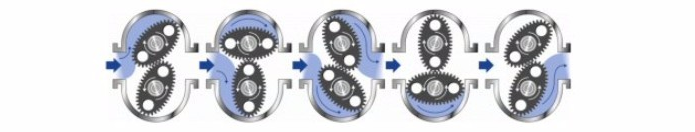

Oval gear flow meter is one of positive displacement flow meter and is mainly composed of meter shell, oval gear rotor and converter. It is an instrument used for continuous or discontinuous metering and control of liquids in the pipeline. It has advantages of large metering range, excellent accuracy, small pressure loss and high viscosity adaptability.

It has good performance on measuring high-temperature and high-viscosity liquids. It is applicable to the calibration and metering of crude oil, chemical, chemical fiber, traffic, commerce, food, medicine and health, scientific research and military etc.

Flow meter is installed in the metering tank and the measurement of a pair of oval box gear, with the upper and lower cover an early Lunar sealed cavity (due to rotation of the gear, so sealing is not an absolute) as a unit of emissions. When measured by the pipe into the liquid flow meter, due to pressure generated by the Import and Export Department to promote a pair of differential gears for rotation, the constant measurement by cavity after the beginning of the Lunar liquid delivery to the exit, elliptical gear with each revolution time displacement is the product of four times the measured volume of liquid flow.

Applications:

It is widely used in liquid flow control in various industrial fields and is suitable for various types of liquid measurement, such as crude oil,diesel, Gasoline, etc. It has the characteristics of large range, high precision,convenient use and maintenance.

Different manufacturing materials are selected to meet the liquid flow measurement in various fields such as petroleum, chemical industry, medicine, food, metallurgy, electric power, and transportation.

| Transmitter Type |

Pointer Display; Pointer with zero returning; Pointer display with Output; LCD |

| Medium |

Fuel Oil; Petroleum; Petroleum Products; Vegetable Oil; Food; Chemical |

|

Accuracy |

±0.2%; ±0.5% |

|

Nominal Diamete |

DN8~DN200 mm |

| Nominal Pressure | PN1.6~6.3MPa |

| Medium Temperature | -10 °C~280 °C |

| Medium Viscosity | 2~3000mPa•s |

|

Power Supply |

12V DC; 24V DC |

|

Output Signal |

Pulse; 4~20mA.DC; RS485 |

|

Display |

Accumulative Flow, Single Measurement(Mechanical Dial); Remote transmission of total and instantaneous flow |

|

Explosion Proof |

Flame-proof Type, ExdIIBT4 |

|

Ambient Temperature |

-20~55°C |

|

Sensor Material: |

Cast Iron; Cast Steel; Stainless Steel |

|

Sensor Connection |

Flange, Screw, Sanitary Tri-clamp |

Flow Range for Different Model

Cast Iron type (A), Cast Steel type (E), Stainless Steel type (B)

%2C-cast-steel-type-(e)%2C-stainless-steel-type-(b).jpg)

High temperature Cast Iron (TA), Cast Steel type (TE), Stainless Steel type (TB)

%2C-cast-steel-type-(te)%2C-stainless-steel-type-(tb).jpg)

High viscosity Cast Iron (NA), Cast Steel type (NE)

%2C-cast-steel-type-(ne).jpg)

Model Selection

| QTLC | xxx | x | x | x | x | x | x | x | x | x | x | x |

|

Size (mm) |

DN8~DN200mm (1/4”~4”) |

|||||||||||

|

Media viscosity |

2~200 mPa·s |

D | ||||||||||

| 200~1000 mPa·s | E | |||||||||||

| 1000~2000 mPa·s | F | |||||||||||

| 3000~10000 mPa·s | H | |||||||||||

|

Accuracy |

±0.5% (Standard) | 5 |

||||||||||

|

±0.2% |

2 | |||||||||||

|

Body material |

Cast iron |

CI | ||||||||||

| Cast steel | CS | |||||||||||

| SS304 | SS | |||||||||||

|

Media Temperature |

20℃~+100℃ (Standard ) |

L | ||||||||||

| +100℃~+250℃ | H | |||||||||||

| Display | Pointer + Zero return | P |

||||||||||

| LCD + Zero return | L | |||||||||||

| Power Supply | Mechanical type | M |

||||||||||

|

24VDC |

2 | |||||||||||

| 12VDC | 1 | |||||||||||

| Output | No | N |

||||||||||

|

Pulse |

Y | |||||||||||

| 4-20mA | 4 | |||||||||||

| Communication | No | N |

||||||||||

|

RS485 |

R | |||||||||||

| HART | H | |||||||||||

|

Connection |

Flange (DN8~DN200 |

DIN: PN10, PN16, PN25, PN40 | D** |

|||||||||

|

ANSI:150#, 300#, 400#, 600 |

A** | |||||||||||

| JIS:10K, 20K, 30K, 40K | J** | |||||||||||

|

Tri-clamp (DN8~DN80) |

C | |||||||||||

| Thread (DN8~DN150) | T | |||||||||||

| Ex-proof |

With |

N | ||||||||||

| Without | E | |||||||||||